Corporate Training

Corporate Training & Development

Must have heard the phrase:

“ People are the greatest asset of the organization”

Not true actually :

“Great people can be greatest liabilities”

If they are not empowered enough with skills, capabilities and knowledge for doing a particular job productively and efficiently towards the organization’s objective and goals.

So it is mandatory and fruitful for organizations to train and coach their existing and new employees continuously on desired skills and knowledge to achieve organization’s objectives.

At LEANARROWS we offer various training and development programs.

If you are looking for standalone training program(s), needed one can be selected from list of our specially designed training curriculum and we can deliver them at your premises or at our mutually agreed place.

Training Need Analysis

We also offer services where customer wanted to know what training programs are very much needed by their staff and employees.

In this; we perform TNA for customers: Listing of jobs to be performed, preparing skill matrix depicting current and desired level of skill set for each job, performing gap analysis.

As per gap analysis we offer various programs to fulfill the gaps.

After conducting training we re-evaluate and update skill matrix and so on.

Some of the most popular training programs and consulting packages are explained below for customers for ease of selection.

Lean Six Sigma Deployment

We offer consulting services for company wide deployment of Lean Six Sigma methodology.

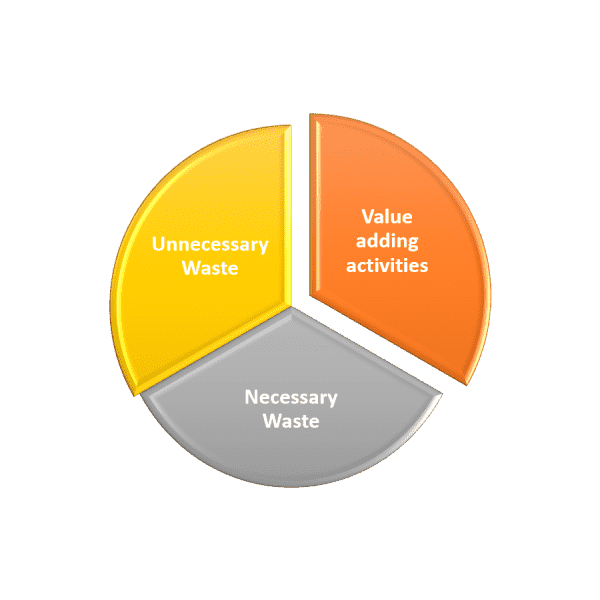

Deployment of Lean Six Sigma Methodology ensure complete cultural change in organization. All non value added activities (NVA) are eliminated from all level of organization i.e. management level, process level and implementation level.

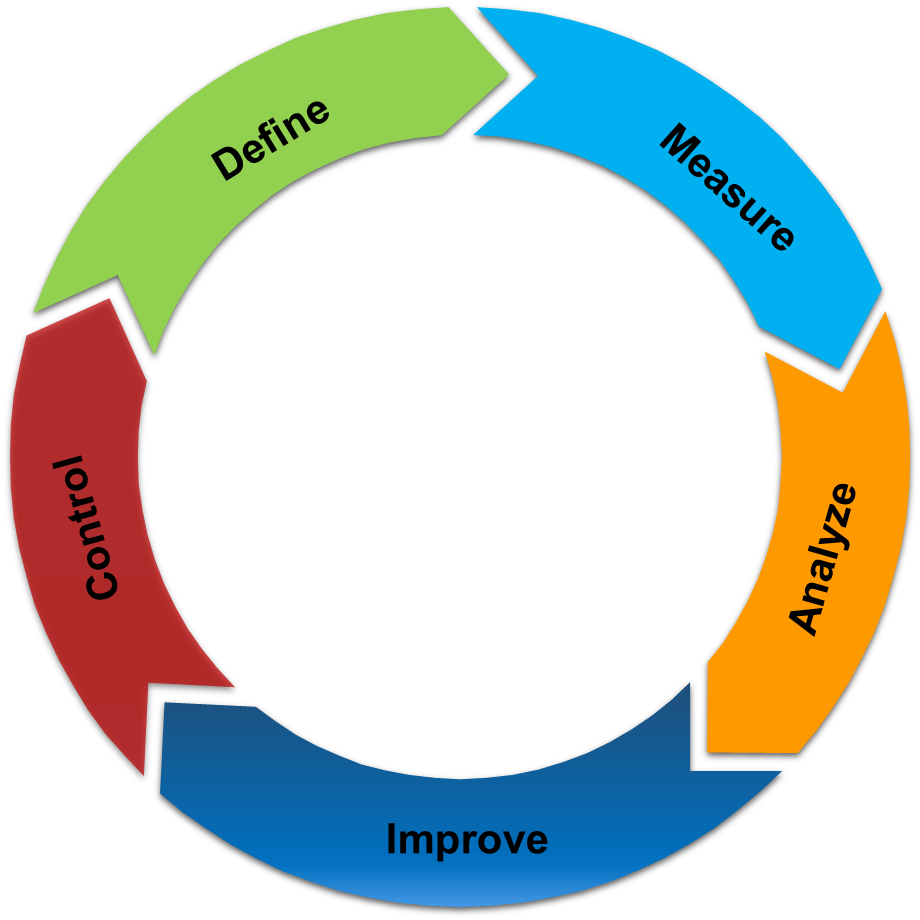

Lean make sure all 7 deadly waste are identified and eliminated where as Six Sigma focusses on all critical-to-quality (CTQ) processes directly affecting customer satisfaction. DMAIC approach is applied to critical processes to achieve almost zero defect (Six Sigma ; 3.4 DPMO).

Deployment starts with establishing Lean Six Sigma organization structure with top management and assigned sponsors and champions.

Projects with high and mid level potential financial savings are evaluated and selected.

Project team leaders and team members are selected.

Conduct 2 days Lean Six Sigma yellow belt (LSSYB) training program. **

Conduct 5 days Lean Six Sigma green belt (LSSGB) training program. **

Projects charter are prepared and approved.

Inter departmental green belt projects are kicked off.

Within department continuous improvement projects (Kaizen) are kicked off.

** Organization can opt to conduct these two training program separately if they choose not to go for complete deployment.

Continuous monitoring, coaching, mentoring and facilitation during projects are provided on timely manner.

Each DMAIC phase deliverables, toll gate sign- off and closure are thoroughly completed and duly approved and signed.

Weekly and bi-weekly project status report is prepared and submitted to top management for review and guidelines.

At end of successful projects, financial savings are vetted and approved by financial head, project closures reports are submitted.

Project teams recognition and reward ceremony are organized.

5S Training & Workshop

5S is one of the simplest yet strong tool in Lean Methodology originally adopted from “Toyota Production System” in Japan.

5S is used extensively in shop floor management in industries although it can be applied to every working and living place i.e. office area, Kitchen, work stations etc.

5S creates a clean, orderly and disciplined work environment ensuring proper organization, neatness, cleanliness, standardization and discipline in company’s housekeeping and workplace management practices.

5S is a precursor for other improvement initiatives to get successfully implemented.

We have experienced organizations spend a lot of money renting space for their smooth operation. 5S implementation ensures more space are freed within existing set up avoiding need to rent more space.

5S implementation ensure less searching of tools and equipment, decreased walking and motion and reduce cost of repair and purchase.

5S results reduced downtime, fewer accidents, fewer mistakes, Improved flow, better use of space enhancing efficiency of working personals resulting in increase of machine productivity.

We offer standalone one day Training program which include 1/2 day class room training and 1/2 day workshop at preselected shop floor area.

We also render services to customers who are willing to set up, develop and implement 5S program to entire organization.

This service include preparing 5S organization structure, 5S organization lay out, 5S reporting, auditing and follow up.

This make sure 5S stay implemented to sustain result.

2 Days Minitab Essential Training

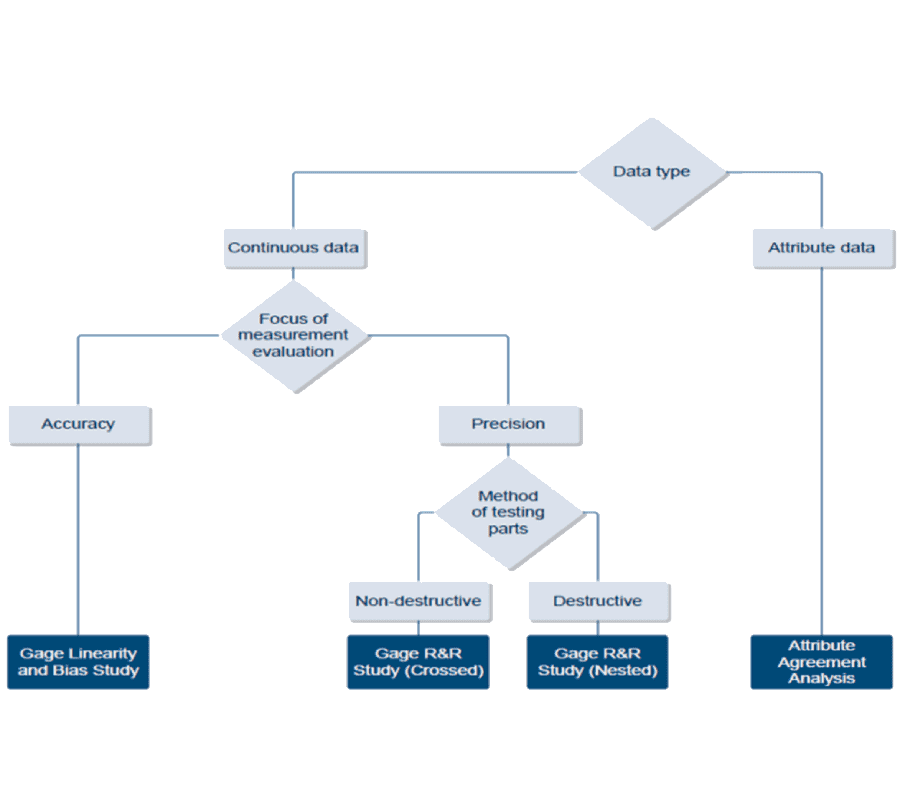

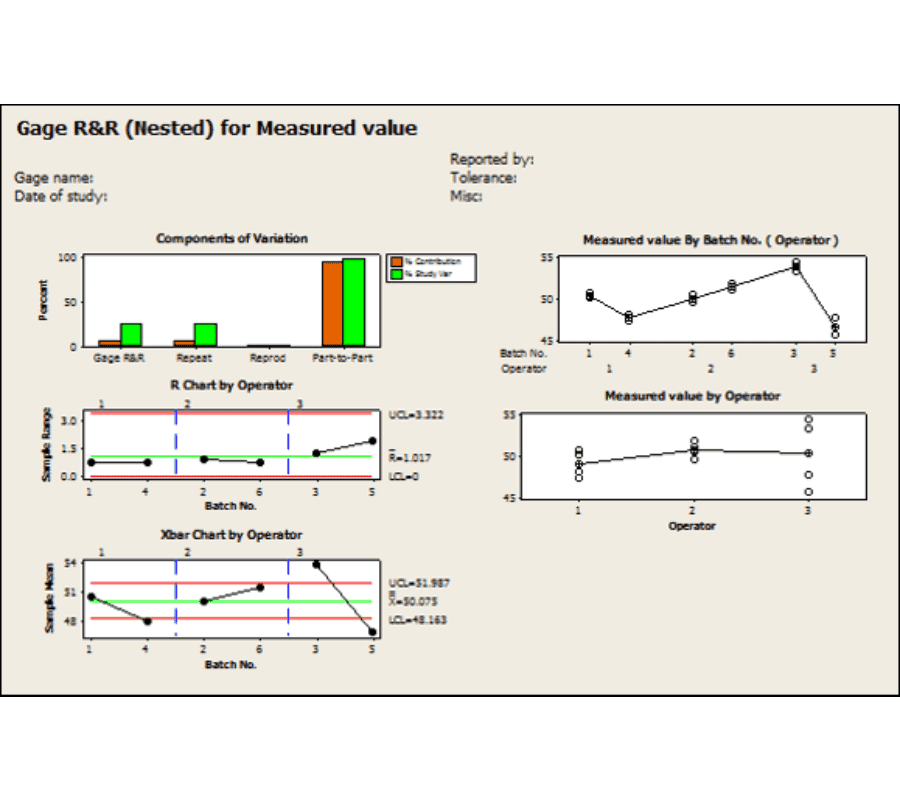

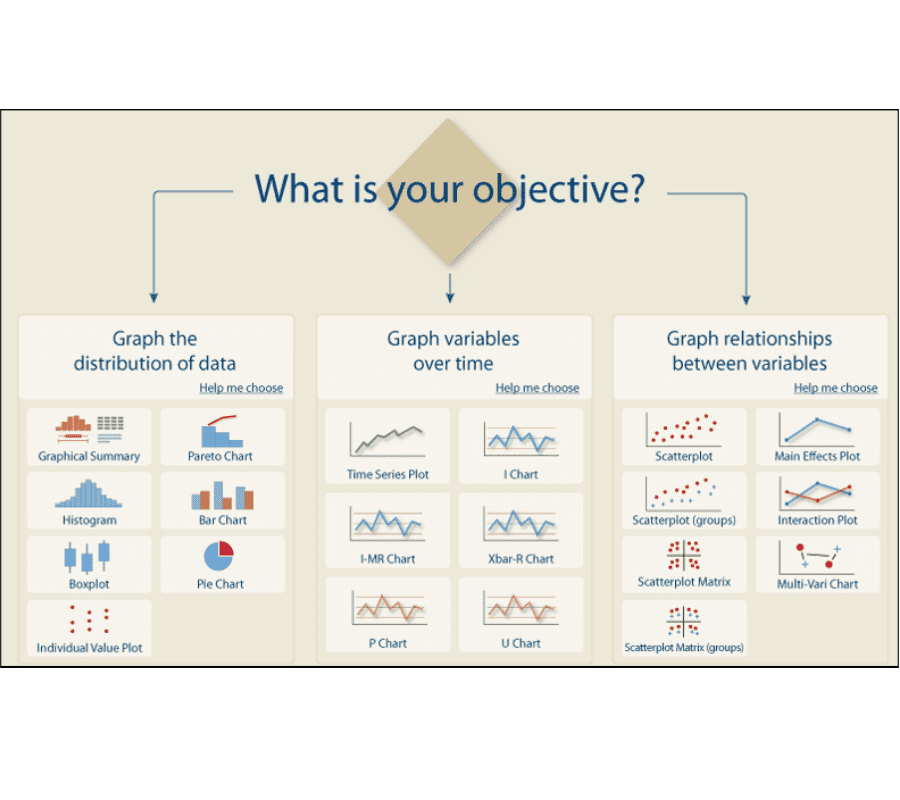

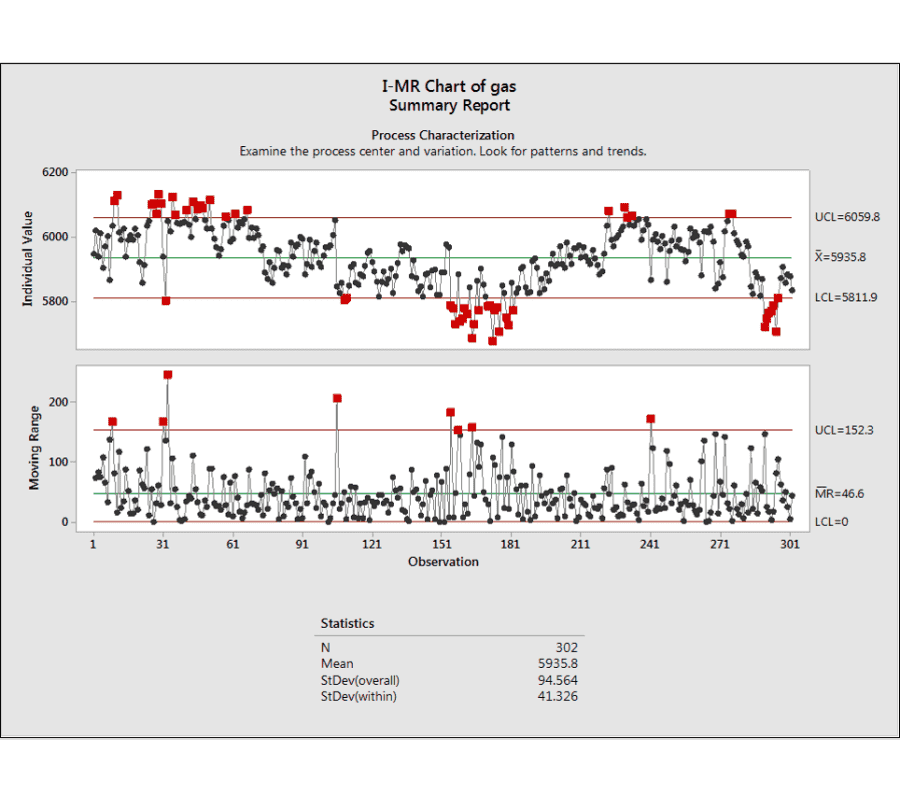

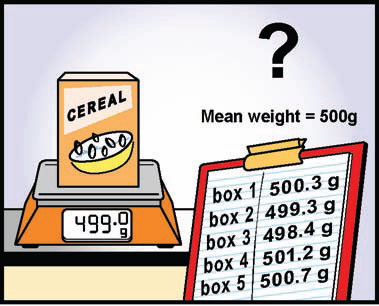

Organizations collect all kind of data to inform current status, predict future scenarios, describe current issues . Based on data analysis they influence business decisions and take decisions.

If the data collection method itself is wrong or incapable so data in hand may be misleading affecting complete decision making process leading to wrong actions and subsequently poor results.

This is a 2 days highly advance, customized and specially designed training program.

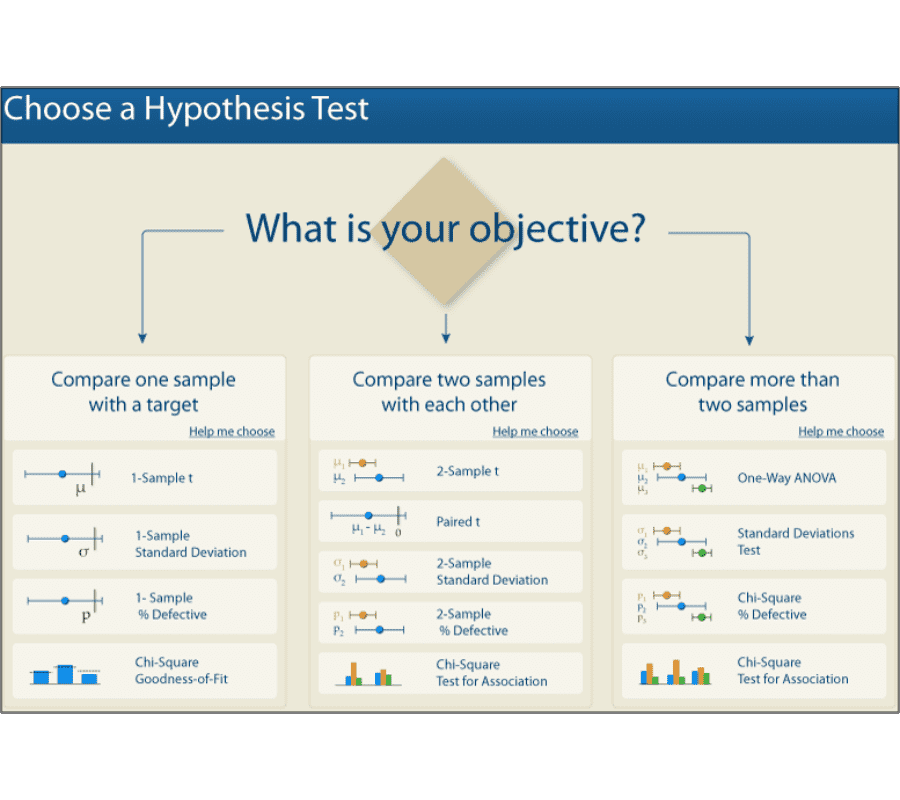

We train business leader and process owners about:

This engaging training program is our one of most popular, and very useful in organizations where plenty of data is collected, it’s analysis and continuous monitoring is needed for world class performances.

Value Stream Mapping (VSM)

“Customer does not pay for Non Value added activities (Wastes)”

Customer can hire us to perform “Value Stream Mapping” for their premium product family.

This service include:

1. Selecting right product family

2. Establishing current state map

3. Future state design

4. Develop implementation plan

At end of the VSM project we usually eliminate 30-50% of non value added activities (Waste) and lay down road map for continual improvement.

Design Of Experiment (DOE)

You are running a process be it in manufacturing, marketing, sales and service or any other, and you have to deal with a lot of inputs (factors) to have your desired output performance and you don’t know:

Then you need to perform Design of Experiment (DOE), and you should be ready for surprise because DOE results will make you think why you were doing as you were. It is so strong the tools is.

**Highly recommended training program for process owners.

Design Of Experiment (DOE) Training

We offer DOE consultancy where we perform a DOE projects at customer site along with delivering 2 days training program. Customers can choose for standalone training program as well.

What you learn:

LEANARROWS

LEANARROWS